Description of 2000L/hour 4040 RO membrane drinking fresh water purifying machine:

Reverse osmosis is a modern purified water treatment technology. Improve the purity of water quality and remove impurities and salts in water through reverse osmosis elements. The purified water we drink everyday is treated by reverse osmosis equipment. The equipment with clear water quality is composed of raw water pump, quartz sand, activated carbon, filter, high-pressure pump and reverse osmosis membrane. Among them, the listed brand Hangzhou Nanfang Pump Co., Ltd. is selected as the water pump, and Huitong membrane element is selected as the RO membrane to ensure the long service life, low noise and low conductivity of the equipment.

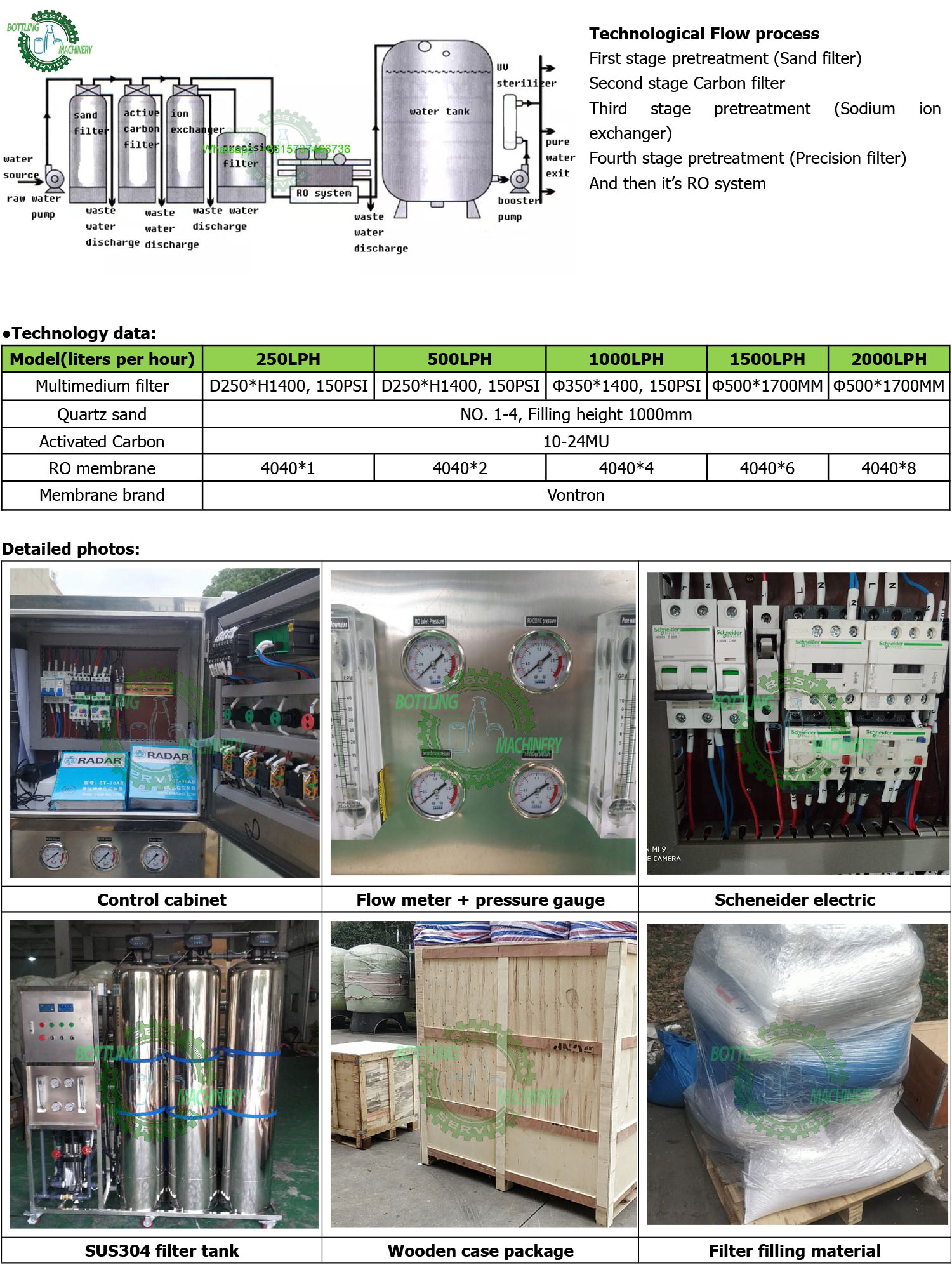

2000l/h reverse osmosis pure water machine system:

The reverse osmosis device uses sufficient pressure to separate the solvent (generally water) in the solution through the reverse osmosis membrane (or semi permeable membrane). Because this process is opposite to the direction of natural osmosis, it is called reverse osmosis. Reverse osmosis can adapt to all kinds of raw water with salt content, especially in water treatment projects with high salt content, and can obtain good technical and economic benefits. The desalination rate of reverse osmosis method is improved, the recovery rate is high, the operation is stable, the floor area is small, and the operation is simple. While desalinating, the reverse osmosis equipment also removes most bacteria, colloids and high molecular weight organics.

1. Prepare pure water and high-purity water required for the production of electronic industry, such as kinescope glass shell, kinescope, liquid crystal display, circuit board, computer hard disk, integrated circuit chip, monocrystalline silicon semiconductor and other processes;

2. To produce softened water and demineralized pure water for heating and thermal power boilers, and feed water for medium and low pressure boilers in factories and mining enterprises;

3. Prepare medical infusion, injection, medicament, pure water for biochemical products, medical sterile water and pure water for artificial kidney dialysis required by the pharmaceutical industry;

4. Making pure drinking water, distilled water, mineral water, liquor brewing water and pure water for blending in the beverage (including liquor) industry;

5. Making domestic water and drinking water from seawater and brackish water;

6. Preparing deionized water for electroplating process; Pure water for battery (storage battery) production process; Surface coating and cleaning of automobiles, household appliances and building materials; Pure water for coated glass; Desalting water for textile printing and dyeing process;

7. Petrochemical industry, such as chemical reaction cooling water; Process pure water used in the manufacturing process of chemical agents, fertilizers, fine chemicals and cosmetics;

8. Water supply network system of hotels, buildings, community airports and real estate properties and water purification of swimming pools;

9. Circuit board, electroplating, electronic industry wastewater treatment and reuse;