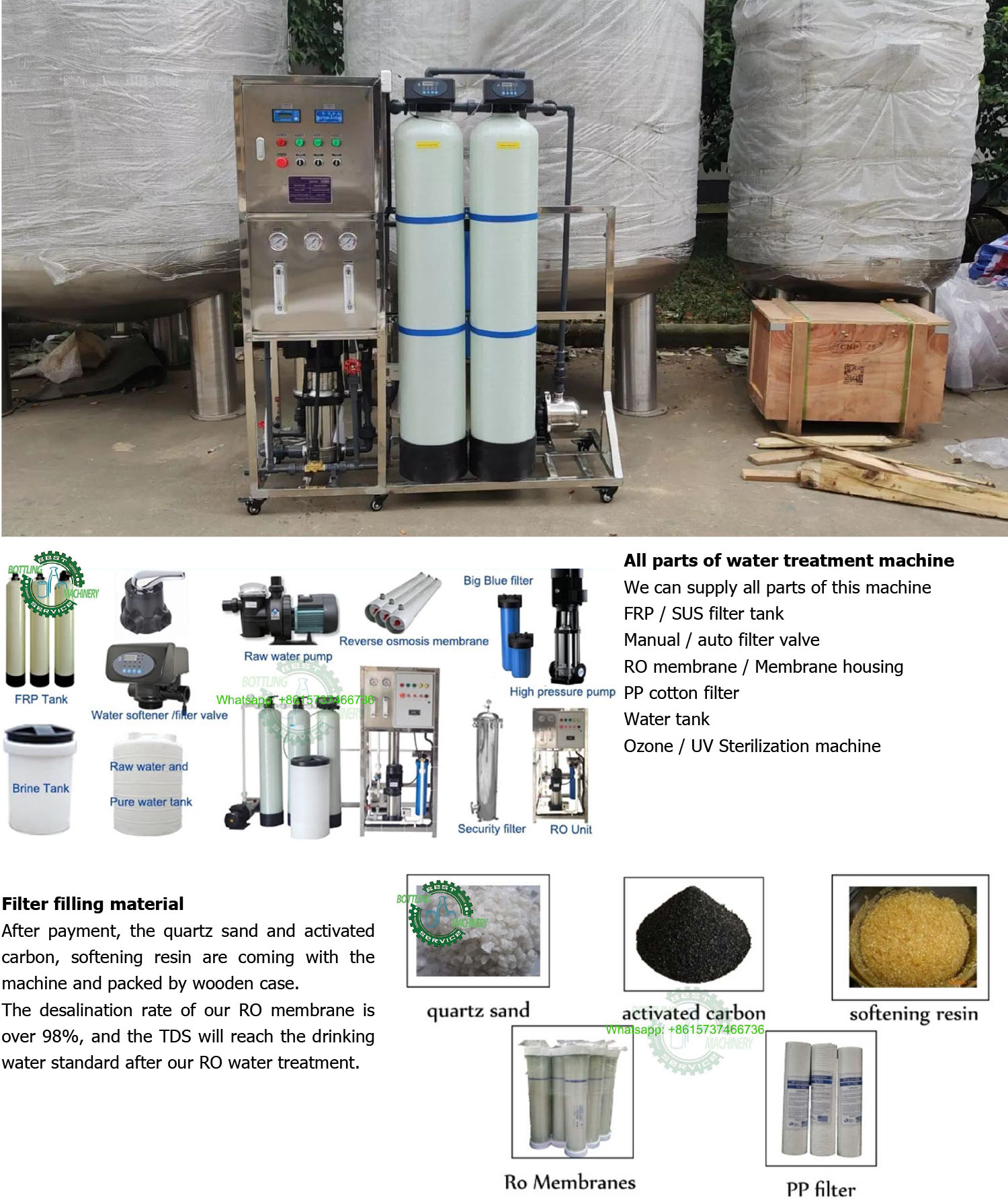

Description of 500LPH Reverse Osmosis Pure drinking water processing machine:

Introduction to reverse osmosis water processing machine:

Reverse osmosis is a membrane separation technology driven by pressure with the help of selective permeable (semi permeable) membranes. When the pressure applied in the system is greater than the osmotic pressure of the influent solution, water molecules continuously pass through the membrane, flow into the central pipe through the water production channel, and then flow out of the water at one end. Impurities, such as ions, organics, bacteria, viruses, etc., are intercepted at the water inlet side of the membrane, and then flow out at the concentrated water outlet, So as to achieve the purpose of separation and purification.

Technical indicators of reverse osmosis water processing machine:

1. water production: 500l/h (25 ℃)

2. effluent quality: reverse osmosis effluent conductivity <10us>98%, used for production process water.

3. raw water quality: municipal tap water

4. design boundary: all pipelines, valves and electric controls from the inlet of raw water tank to the pure water tank

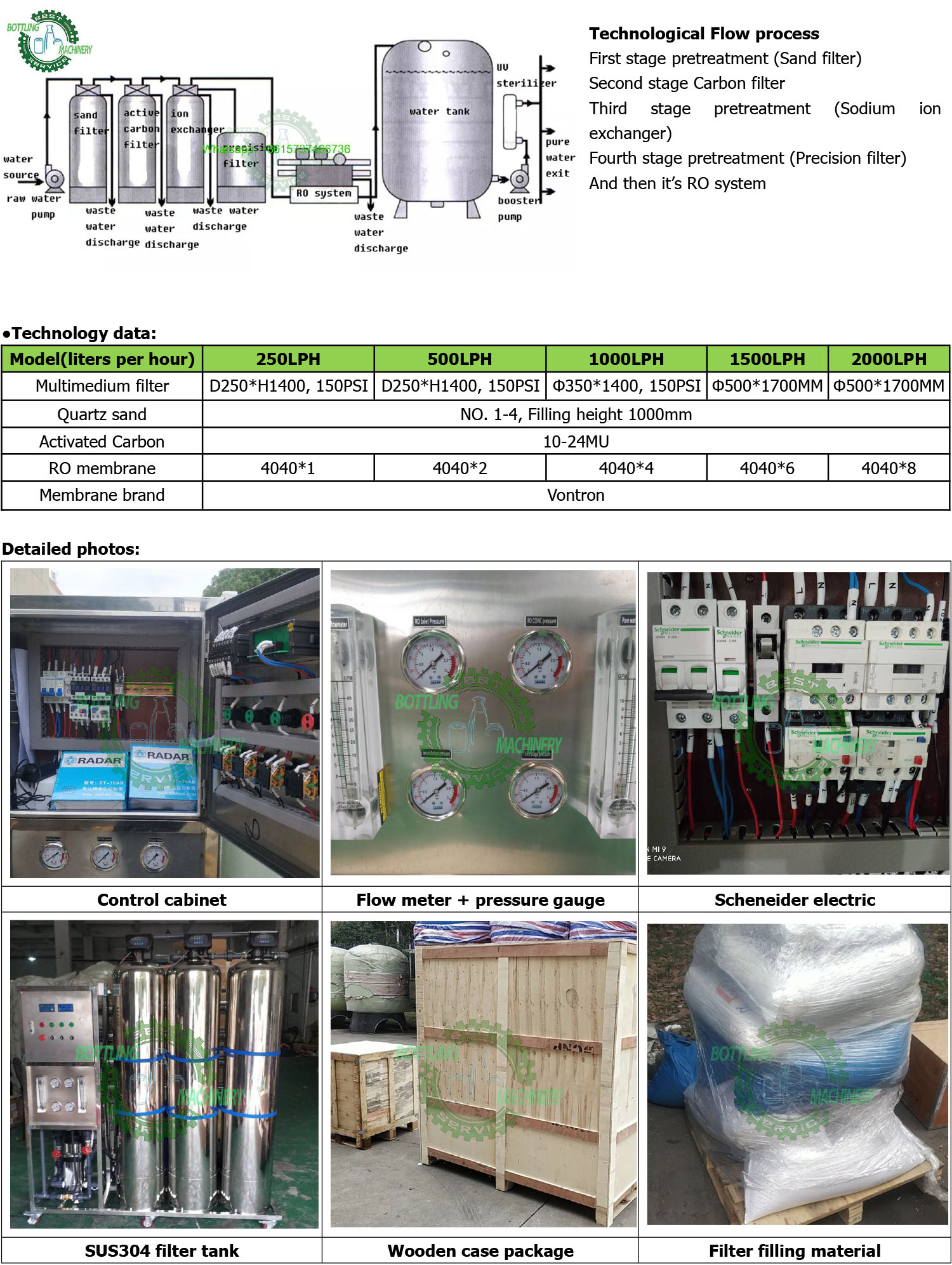

5. process flow: tap water – raw water tank – water supply pump – multi-media filter – activated carbon filter – softening filter – security filter – high pressure pump – reverse osmosis unit – pure water tank

Reverse osmosis water processing machine electrical control design:

1. PLC control, fully automatic operation, and unattended 24-hour continuous water production.

2. if the tap water supply is insufficient, the water preparation system will automatically shut down for protection; The water supply is normal, and the system automatically resumes operation.

3. if the water level of the pure water tank is full, the water making system will automatically stop making water. If the water level is normal, the system will automatically return to work.

4. whenever the reverse osmosis system works, the system will automatically flush the reverse osmosis membrane according to the procedure, and then start normal water production.

5. the reverse osmosis system has high-voltage protection, low-voltage protection and motor overheat protection. Prevent damage to equipment due to human error

Precautions for use of reverse osmosis water processing machine:

1. The water yield of this machine is above 500l/h when the water temperature is 25 ℃. When the water temperature increases or decreases by 1 ℃, the water yield will increase or decrease by about 3%, which is determined by the characteristics of RO membrane.

2. The residual chlorine content of the water entering the RO membrane shall be strictly controlled below 0.1ppm. Yes: the sampling port of the adsorption filter is connected with water and tested with residual chlorine measuring agent. If it exceeds the standard, the activated carbon filter material shall be replaced.

3. If the water inflow is insufficient or the pressure is too low, the water shortage and undervoltage system of the machine will automatically shut down the equipment.

4. During the initial use of the machine, due to the preservative contained in the RO membrane, the effluent conductivity will be high. After washing for 1-2 hours and making water normally for a period of time, the effluent conductivity will be significantly reduced.