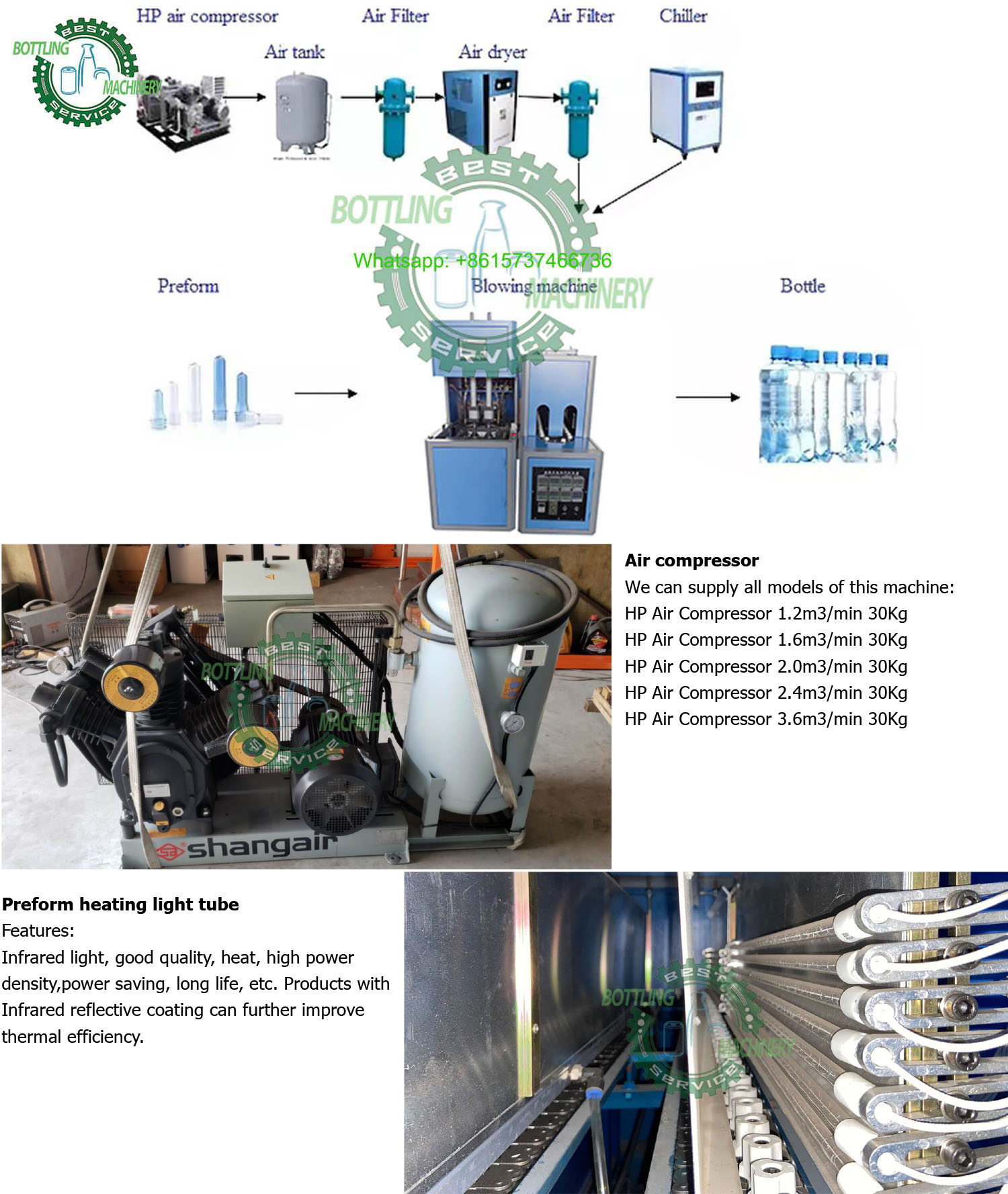

Description of semi auto 1000BPH 50ml-2000ml PET bottle blow moulding machine:

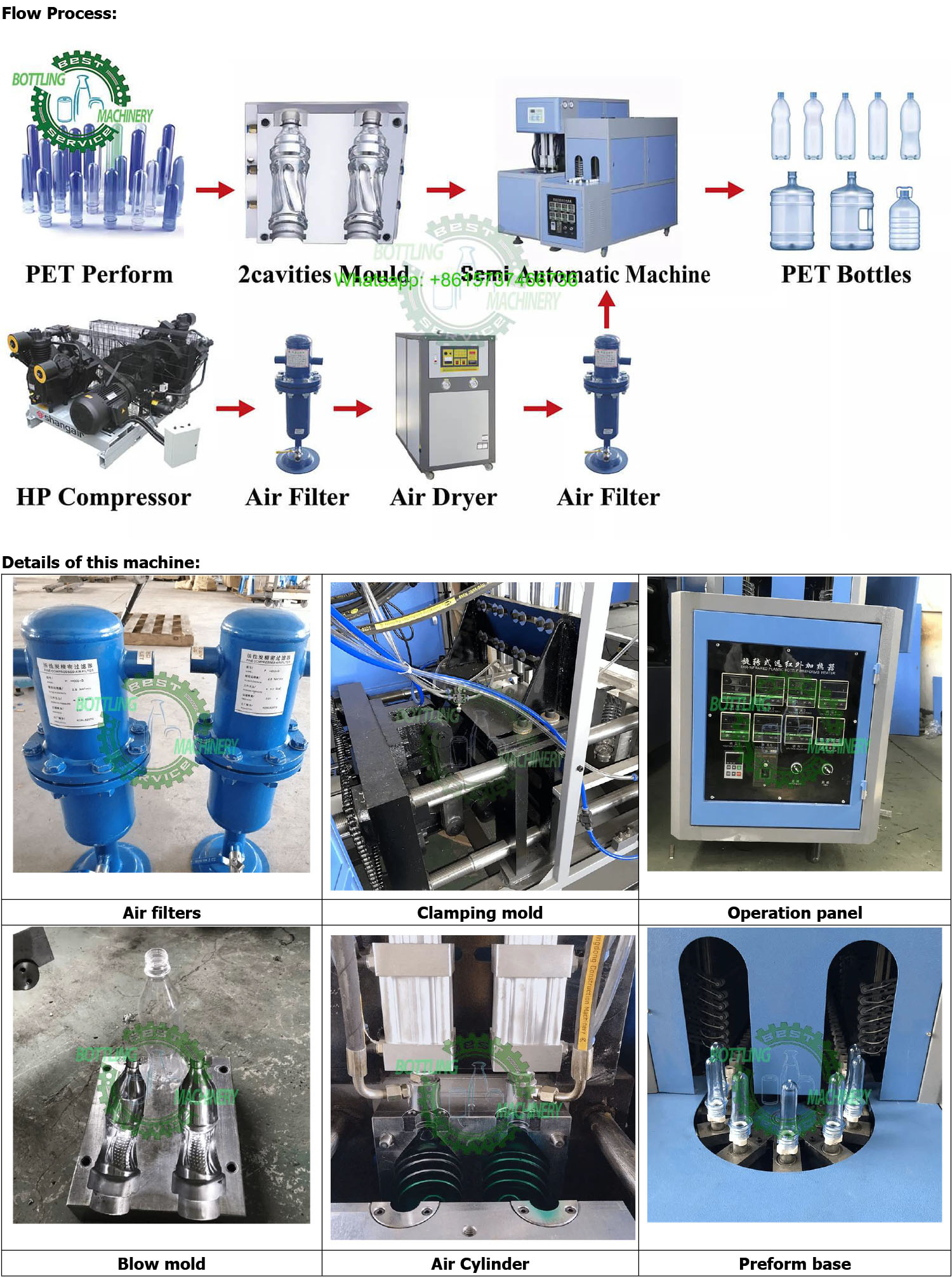

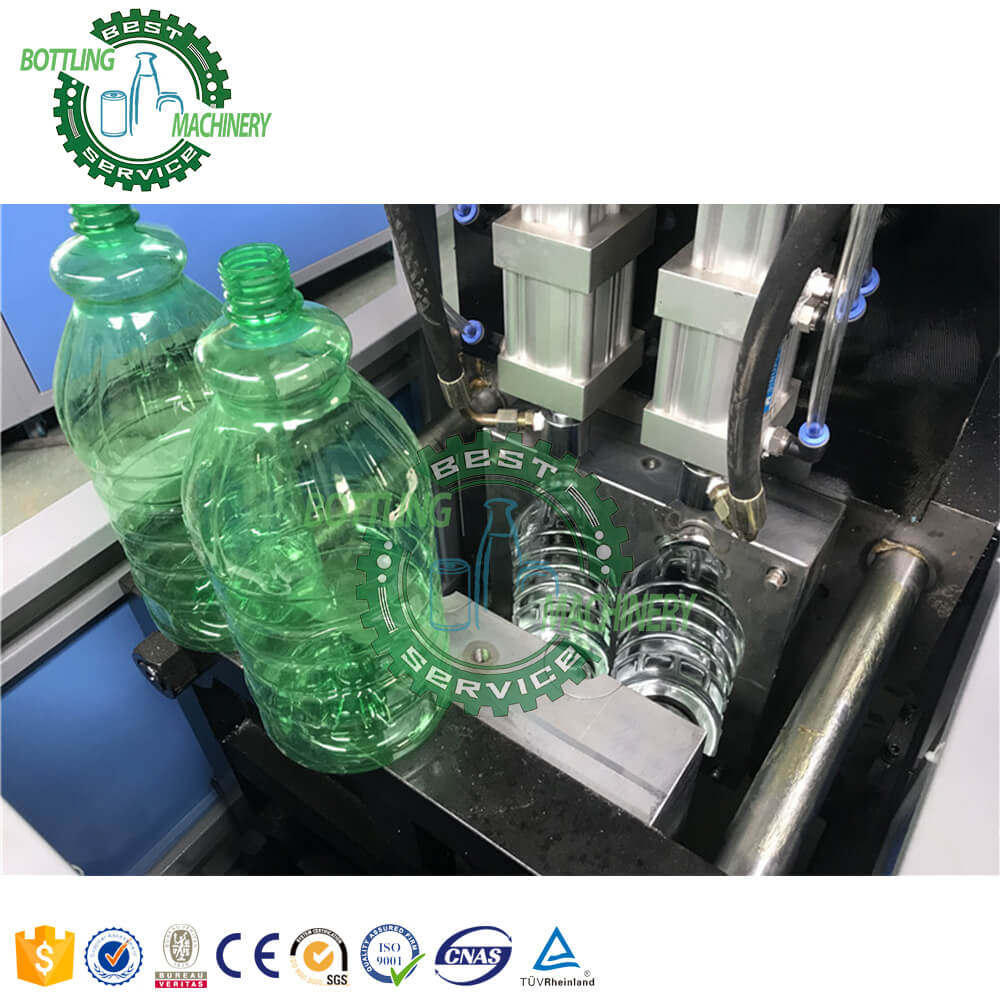

BL-1200A 2 cavity Bottle blow moulding machine is a two-step semi-automatic stretching bottle blowing equipment. It is suitable for manufacturing plastic bottles with pet as raw material, and is widely used for manufacturing carbonated beverage bottles, mineral water bottles, oil bottles, medical bottles, cosmetics bottles, and large caliber bottles and hot filled bottles with accessories. The controller is controlled by PLC (time relay can be selected), which is convenient for maintenance and low in cost. The time control can be accurate to 0.01 seconds. The air circuit design divides the action and blowing into two parts to meet the requirements of different air pressures for bottle blowing and action. The far infrared heater is heated by frequency conversion autorotation, and the rail revolution makes the heating even, fast and reliable. Different segmented heating lamps are equipped with independent temperature control devices to ensure ideal heating effect of bottle embryo. The direction of the heating lamp tube can be adjusted according to different bottle embryos. Only one person is required for operation, no special training is required, and installation and startup are simple.

Characteristic of BL-1200A semi auto bottle blow moulding machine:

1. Special electric control circuit is adopted to design lamp tube heating, which can adopt single or multiple synchronous control with high efficiency and reduce power consumption.

2. Heat transfer analysis and feedback theory are applied to set the temperature of the heating box according to the shape and thickness of the bottle embryo.

3. The bottle embryo is free from external environmental factors and evenly heated.

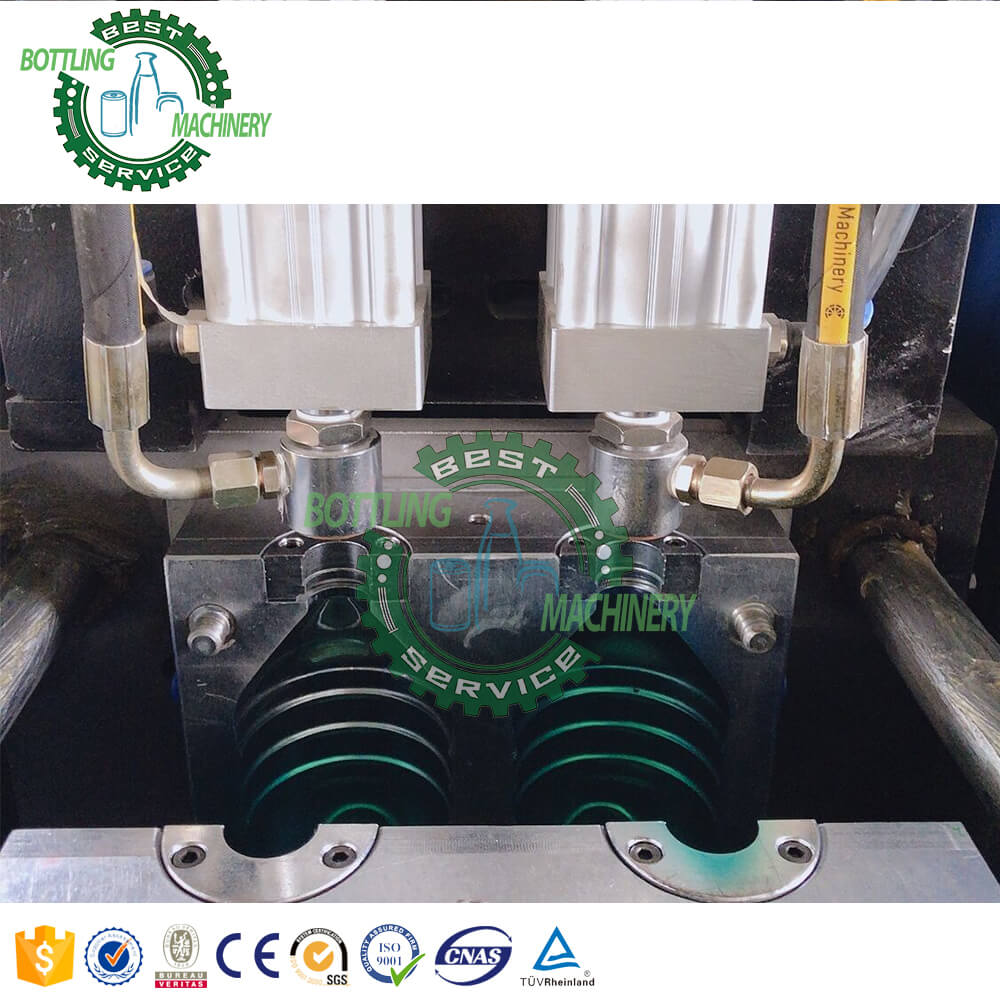

4. The air circuit system is divided into two parts, namely, action and blowing, to meet the requirements of different air pressures for action and blowing, and to provide stable high pressure to blow shaped large volume bottles.

5. The system is equipped with muffler, connecting rod and crank arm refueling device.

6. The operation is divided into two modes: inching and semi-automatic.

7. Small size, less investment, one person operation, simple and safe.

8. The cold air circulating cooling system can ensure the consistency of the heating of the inner and outer walls of the preform.

评价

目前还没有评价