Description of 30000LPH 30ton/hour 30m3/h RO reverse osmosis Water purification plant:

30t / h (30000l/h) pure Water purification plant, pure water equipment, ultra pure water equipment, reverse osmosis equipment, water treatment equipment.

Main uses of the equipment: drinking water, purified water production, boiler make-up water, food processing and pharmaceutical production water.

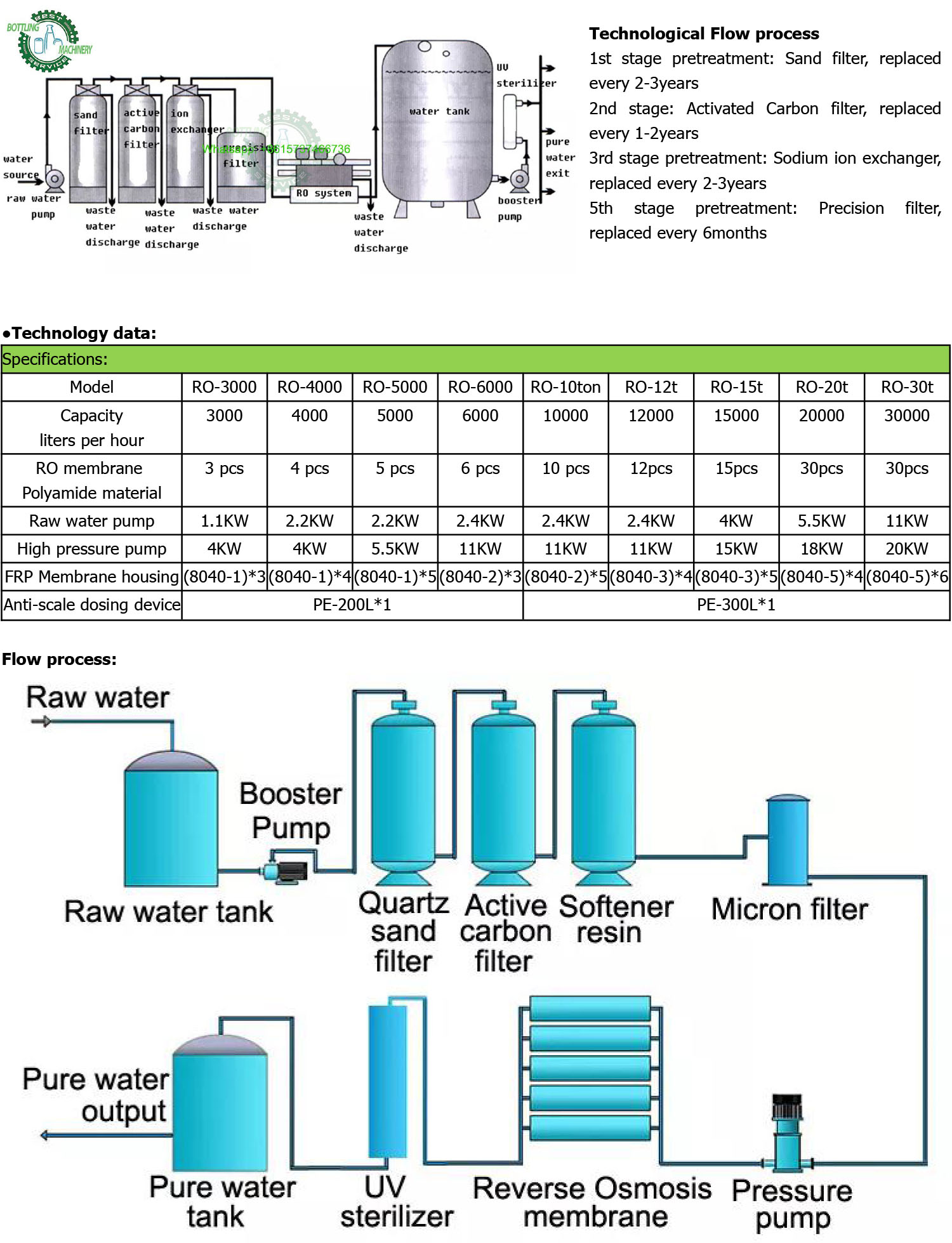

I Technical parameters of Water purification plant:

1. Water production of equipment: 30000l/ hour (water production of equipment is 30 tons per hour)

2. Water quality of equipment produced water: Bottled purified drinking water standard and hygienic standard GB17324-2003

3. Conductivity of product water <10 μ S/cm

4. Size of equipment host: 3100 × two thousand and eight hundred × 2000MM

5. Equipment power demand: three-phase four wire braking power or two-phase power

6. Water supply demand of equipment: more than 60 cubic meters / hour

7. Power consumption of equipment: 30KW

8. RO membrane: 30 cpa3-8040 reverse osmosis membranes

II Equipment features of Water purification plant:

1. Liquid level protection function of raw water tank: if the pure water in the pure water tank exceeds the high liquid level, the controller will shut down * * *. Restart if the liquid level falls back***

2. Anhydrous protection function: if the raw water is cut off, the controller will shut down the whole RO system to prevent the pump from empty pumping. If the water supply is restored, the system will be restarted automatically.

3. Liquid level protection function of pure water tank: if the pure water in the pure water tank exceeds the high liquid level, the controller will shut down the whole RO system. If the liquid level drops, restart the system. The two water tanks are interlocked.

4. Low voltage protection function: if the low voltage is insufficient, close the whole RO system

5. High pressure protection function: if the high pressure is overpressured, the controller will shut down the whole RO system

III Equipment process description of water filtration plant:

1) Raw water pump:

Main functions: constant system water supply pressure and stable water supply

2) Mechanical filter:

The filter with multiple filter is mainly used to remove sediment, rust, colloidal substances, suspended solids and other substances with particles of more than 20um in the raw water. The system can carry out a series of operations such as backwashing and forward flushing. Main functions: ensure the water production of the equipment and extend the service life of the equipment.

3) Activated carbon filter:

Using the nut shell activated carbon filter, activated carbon can not only adsorb electrolyte ions, but also carry out ion exchange adsorption. Activated carbon adsorption can also reduce the oxygen consumption (COD) of potassium permanganate from 15mg/l (02) to 2-7mg/l (02). In addition, the concentration of adsorbed replication on the surface increases due to adsorption, which also plays a catalytic role, removing pigments, odors, a large number of biochemical organics, reducing the residual halogen value of water and pesticide pollutants, and removing trihalides (THM) and other pollutants in water. The system can carry out a series of operations such as backwashing and forward flushing. At the same time, the equipment has a self-maintenance system, and the operation cost is very low. Main functions: ensure the water production quality of the equipment and extend the service life of the equipment

4) Softening system:

In order to prevent the concentration of CaCO3, MgCO3, MgSO4, CaSO4, BaSO4, SrSO4 and siso4 at the concentrated water end, especially at the concentrated water side of a membrane module of RO device, from crystallization and precipitation when the concentration is greater than its equilibrium solubility constant, and damage the characteristics of the membrane element, the system adopts sodium cation exchange resin for ion exchange adsorption before entering the reverse osmosis membrane module to remove the main hardness components in the water. After the adsorption is saturated, the resin fails, Industrial salt can be used to regenerate the resin to restore its exchange capacity. Each softening system includes: softening tank, controller (or fluidizer / salt pump), salt tank and salt valve. Main functions: prevent reverse osmosis from scaling and prolong the service life of reverse osmosis membrane

5) Precision filter:

The precision filter is used to intercept a small amount of mechanical impurities leaked by the pretreatment system. The filter cylinder is made of engineering plastic or SUS304; PPF filter element is installed inside. Polypropylene filter element is a deep filter element with low resistance. It is suitable for further purification of water with low suspended impurities (turbidity less than 2-5 degrees). Polypropylene filter element is formed by wrapping polypropylene fiber on the injection molded polypropylene porous pipe according to a certain law.

6) Main functions of osmosis reverse water treatment system

Ensure that the particle size of water entering the reverse osmosis membrane is less than 0.1um 6 high-pressure pump, because the reverse osmosis membrane requires high pressure during the working process. The high-pressure pump is the main operating equipment of the reverse osmosis system and provides a power source for the operation of the reverse osmosis device. Multistage vertical centrifugal pump is selected for this system. The material is SUS304, which has the characteristics of beautiful appearance, small floor area, low noise = maintenance free. The water inlet of the high-pressure pump is protected by a low-pressure protection switch. When the water inlet pressure is lower than the set value (0.05Mpa), the high-pressure pump is stopped to prevent the high-pressure pump from being evacuated and damaging. The water inlet of the high-pressure pump is protected by a high-pressure protection switch. When the water inlet pressure is higher than the set value (2.0MPa), the high-pressure pump is stopped to protect the high-pressure pump and the membrane module from damage

7) Reverse osmosis system:

The reverse osmosis device uses enough pressure to separate the solvent (generally water) in the solution through the reverse osmosis membrane (or semi permeable membrane). Because this process is opposite to the direction of natural osmosis, it is called reverse osmosis. After reverse osmosis treatment, the content of impurities in water is reduced, and the purity of water quality is improved. Its desalination rate can reach more than 97%, and most of the bacteria, colloids and high molecular weight organics in water can be removed. Reverse osmosis can adapt to all kinds of raw water with salt content, especially in water treatment projects with high salt content, and can obtain good technical and economic benefits. The desalination rate of reverse osmosis method is improved, the recovery rate is high, the operation is stable, the floor area is small, and the operation is simple. In the past, due to the high price of reverse osmosis facilities. It has hindered the promotion and use of reverse osmosis equipment, but in the past two years, the price of reverse osmosis facilities has been declining, making reverse osmosis equipment * * * used in all kinds of demineralized water treatment projects. Because reverse osmosis equipment removes most bacteria, colloids and macromolecular organic substances while desalting, reverse osmosis equipment is even more indispensable in the preparation of pure water.

8040 reverse osmosis membrane performance characteristics:

Cpa3-8040 membrane element is mainly aimed at surface water and groundwater with low to medium salinity. It can achieve the same high water flux and high desalination rate as the conventional low-pressure membrane under extremely low operating pressure. Its operating pressure is about 2/3 of that of conventional low-pressure composite membrane, and the desalination rate can reach 99.5%. Because the operating pressure is low, the water yield is high, and the desalination rate is high, the economic benefit is obvious